DFCS 1000

Dual Flow Cold Spray 1000

The Dual Flow Cold Spray (DFCS) Machine has been designed to apply a variety of coatings in suitable work environments. The machine’s design, nozzles and other components have been optimized for fast, efficient, high-quality coating.

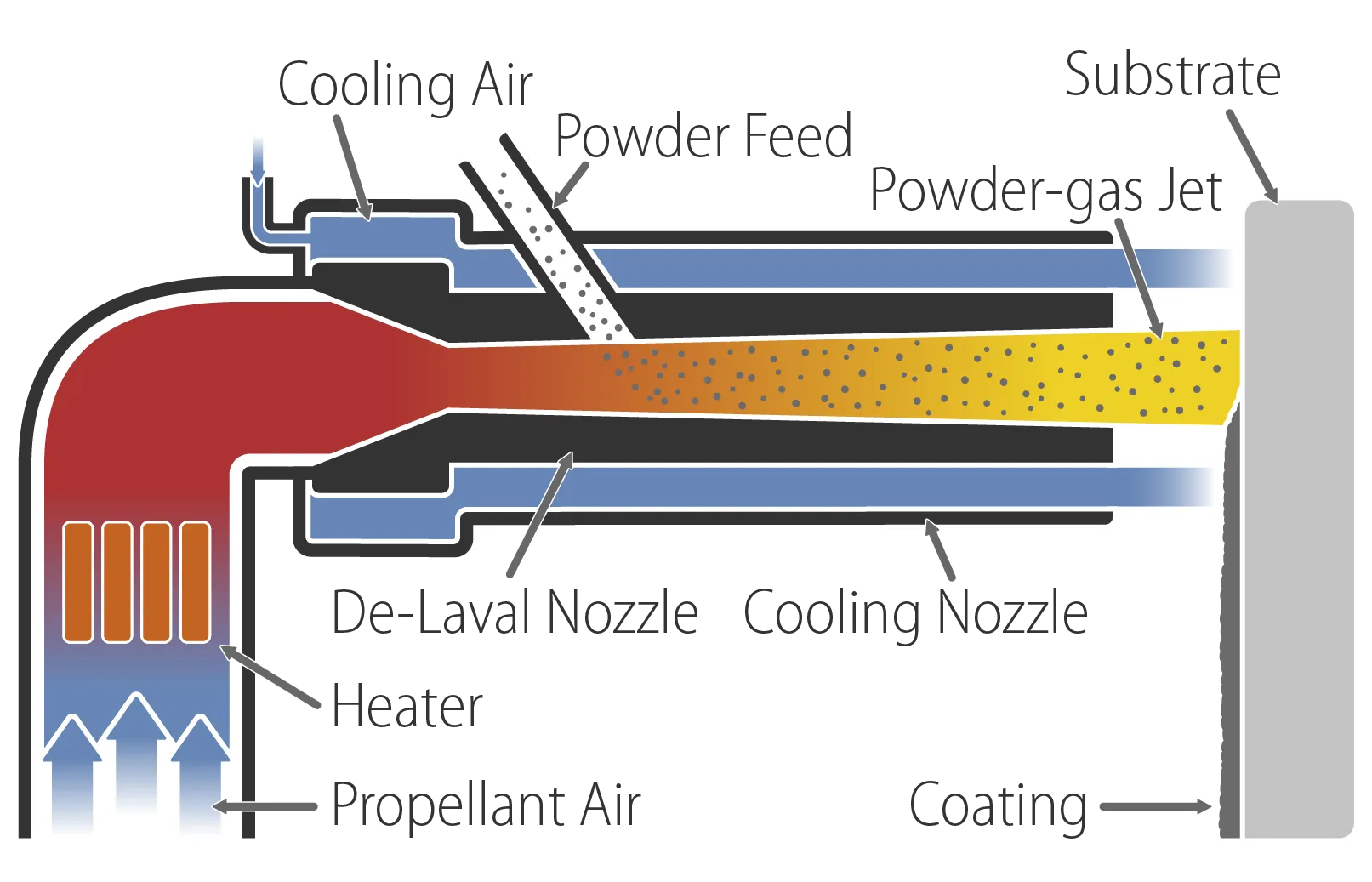

DFCS works on the same principles as LPCS (Low Pressure Cold Spray) technology: the energy of compressed gas is used to propel fine metal or ceramic particles (1-100 microns) at supersonic velocities. Upon impact the particles form a dense coating on the substrate. For DFCS an additional (secondary) cooling flow is added to surround the primary spray nozzle. This technique has multiple benefits for both the coating and substrate. As the name implies, cold spray is a low temperature process in which bulk particles do not melt. A variety of powders including metal, ceramic and composite are used to create high quality, low porosity coatings with customized properties.

Once applied, both the coating and treated surfaces are easily painted, restoring the appearance of damaged field assets. If the work piece is treated prior to placement in the field, cold spray can be used to provide proactive protection from corrosion and other physical damage.