RIWA

Real-Time Integrated Weld Analyzer

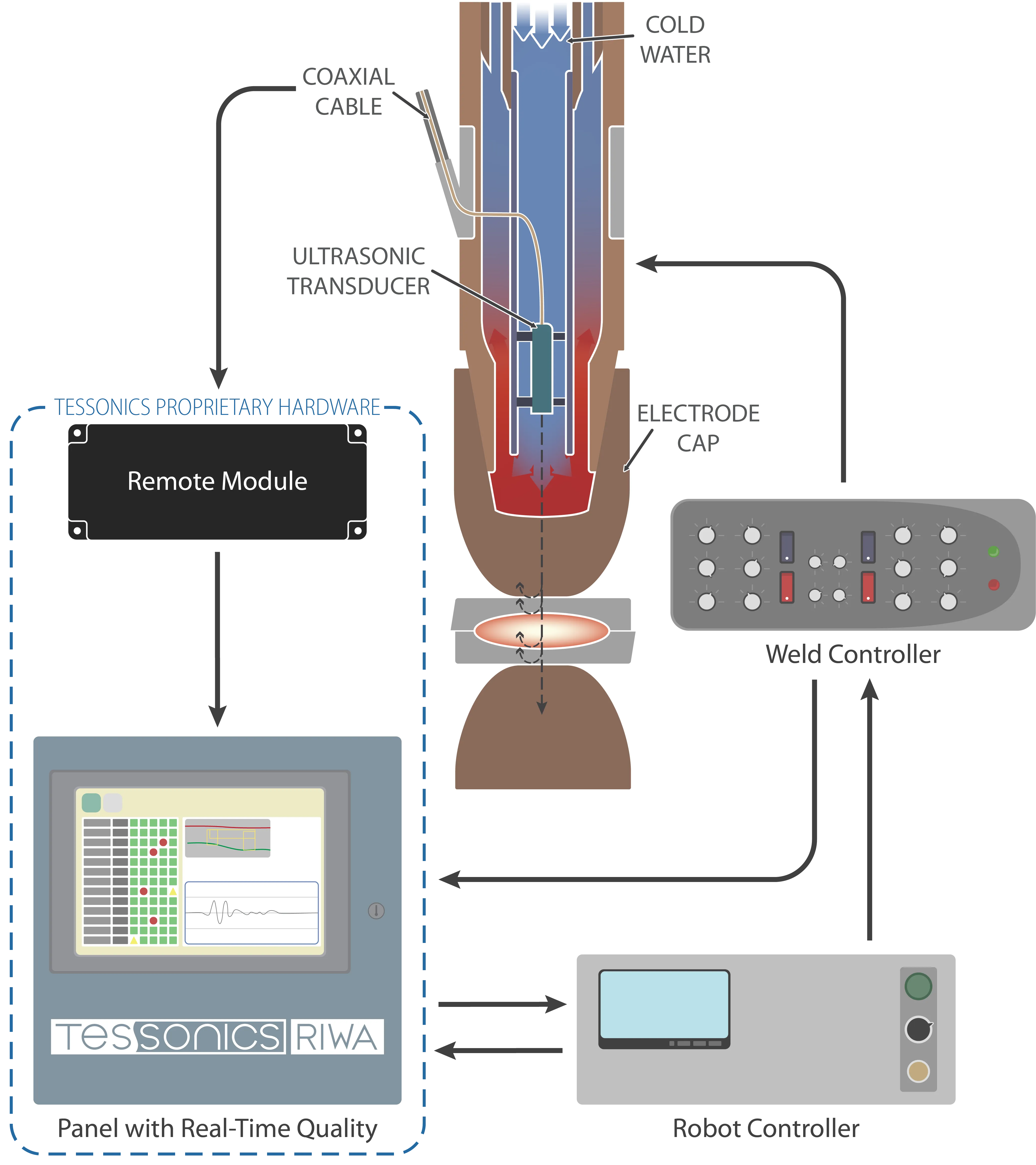

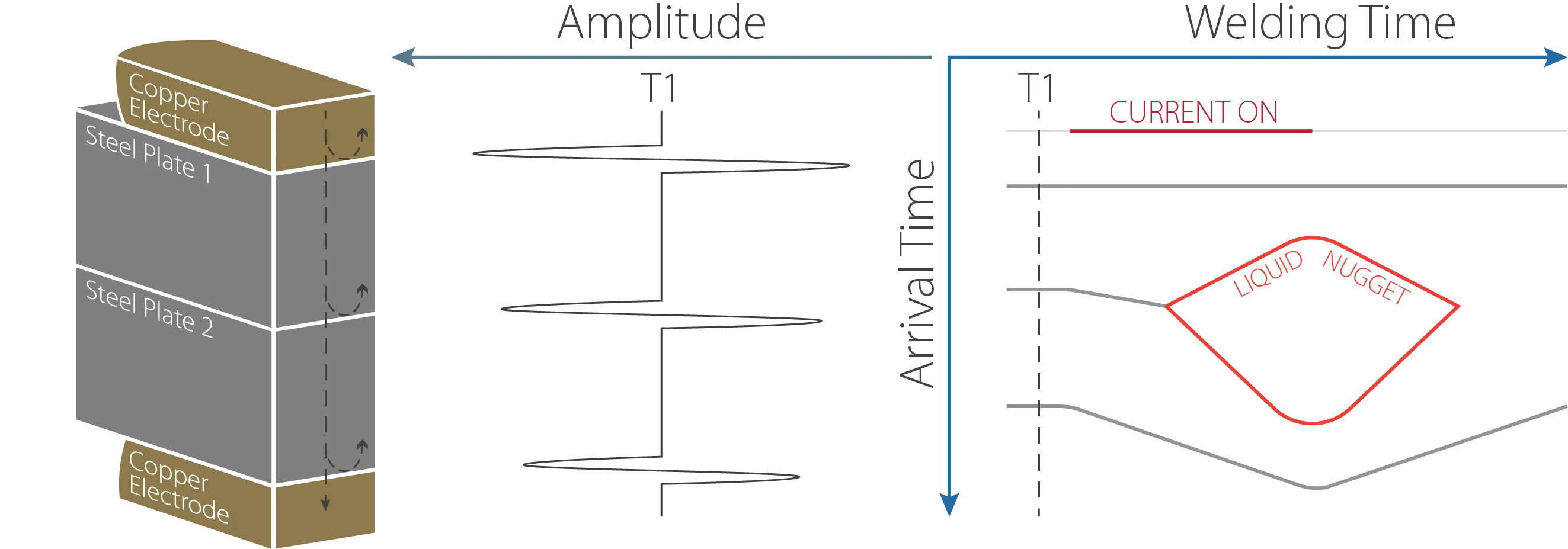

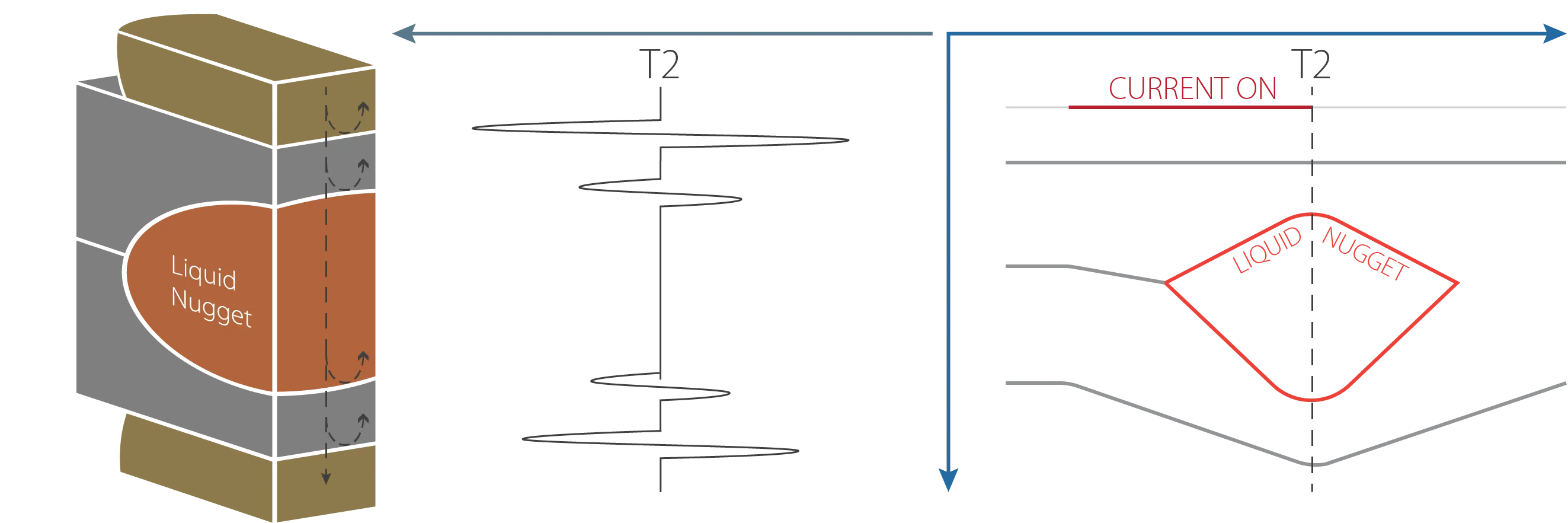

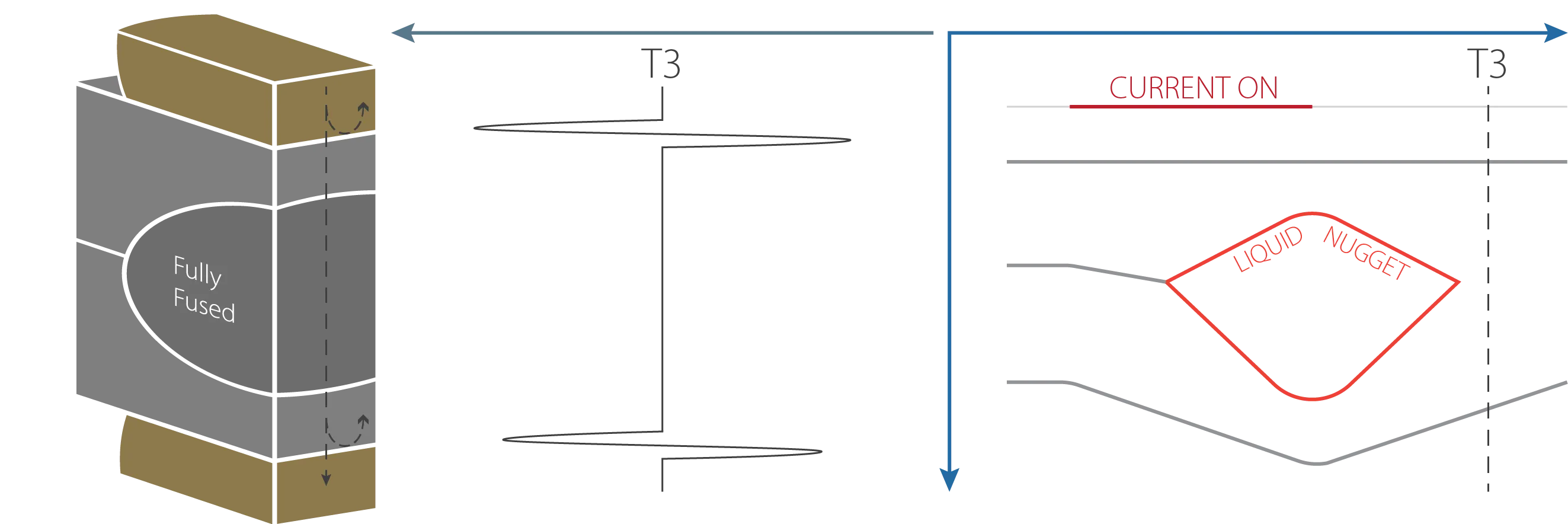

In the new Industry 4.0 environment, RIWA is the Tessonics’ answer for the challenging demands of the new smart factories.The system provides a solution to evaluate resistance spot welds in real-time, using an advanced non-destructive ultrasonic system. A custom built system consisting of a high frequency ultrasonic transducer that is integrated into the welding electrode, which generates ultrasonic waves that pass through the electrode cap into the welded plates. The key feature of the technology is that inspection of the weld is conducted during the real time monitoring of the welding process.

A specialized software, leveraged by the latest advancements in modern processing using AI, is capable of performing full analysis of the weld, reporting the presence of the weld nugget and its location with respect to the plate surface. A fully customizable trigger sensor can be placed to meet quality and process requirements.

RIWA is self-aware, and has the ability to monitor the welding process continuously, becoming a powerful tool in the process management system. The system is shop floor proven, with the expertise of over 20,000 different welding joints behaviours meticulously analysed prior to the build of the detection system.

Features

Metals:

Mild steel

High Strength

Dual phase

Aluminum

Metal Thickness:0.6 - 3.0 mm

Metal Thickness:

Coatings:

Bare

Galvanneal

Galvanized

Data Storage:Software stores millions of weld records on the hard drive

Stored welds can be retrieved for reporting and analysis

Data Storage:

Full System Diagram